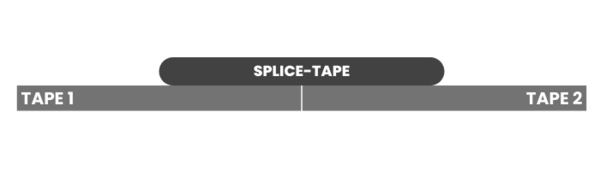

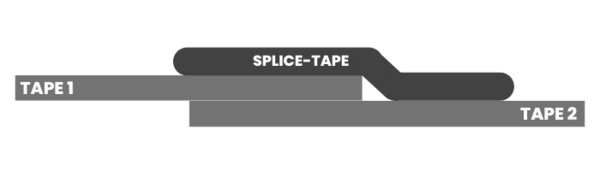

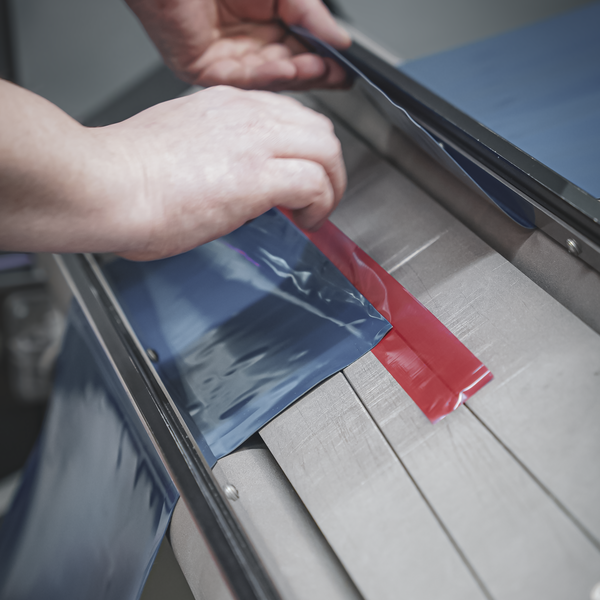

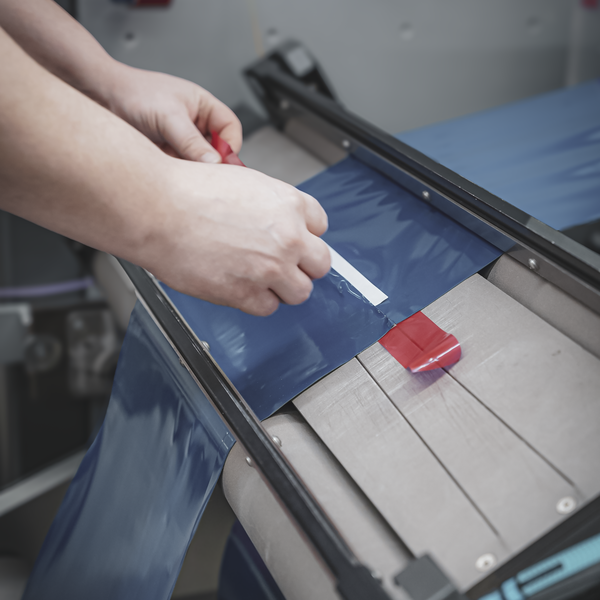

Splicing involves joining two adhesive tape strips together to enable continuous processing.

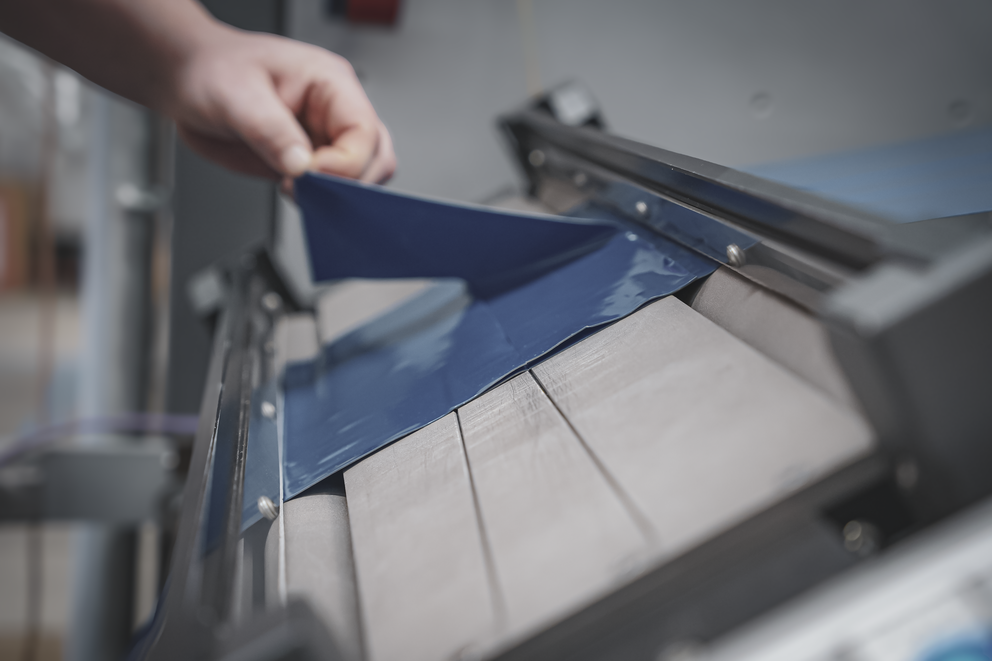

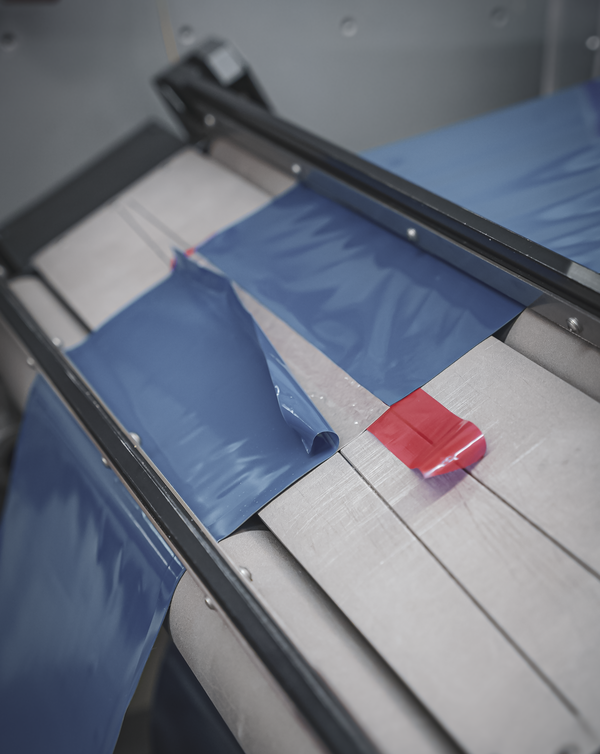

Specifically, this means that a roll of adhesive tape runs through the machine. When this roll is used up, a new roll must be attached so that the process is not interrupted. To do this, the end of the current roll is connected to the beginning of the new roll – this transition is called a splice.

This typically occurs during roll changes, either when the machine is at a standstill or while it is still running.

Important to note: The splice is not a product feature, but rather a process-critical transition within manufacturing. It does not affect the end product itself, but it does affect the path to getting there.

An incorrectly laid splice can cause the web to tear, the machine to stop, tools to be damaged, or dimensional deviations and rejects to occur.