The principle is astonishingly simple, but extremely meaningful. With the so-called ink test, it is possible to assess in seconds whether a substrate is suitable for bonding.

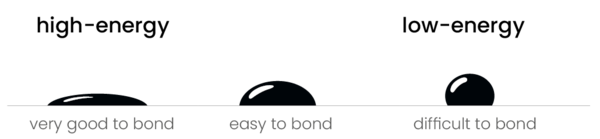

If the ink runs, the surface energy is high. It is sufficiently moistened and therefore easy to stick. If droplets form instead, the surface energy is low and adhesion is correspondingly more complex.

This is precisely why the ink test is a standard step in the automotive industry when introducing new materials – before adhesive formulations or process parameters are discussed.