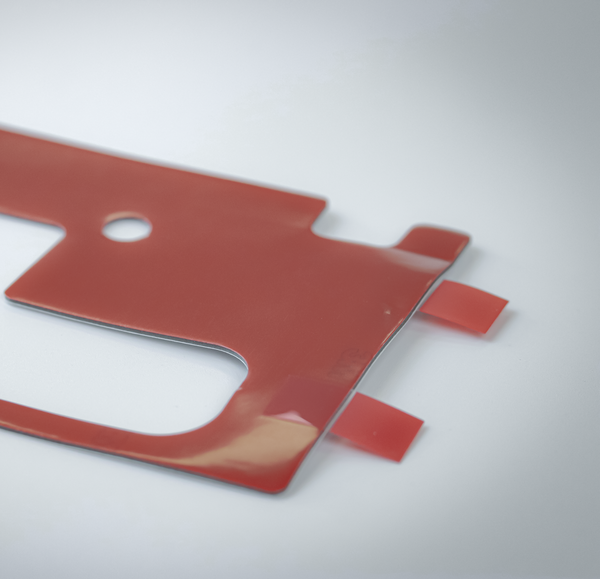

Handling during further processing also plays an important role in ensuring that moulded parts can be glued precisely and easily. For this purpose, so-called pull tabs can be added to the component. These create an area where the part can be handled without touching the adhesive surfaces. The tab protrudes beyond the component and can be designed in different sizes. This makes further processing considerably easier and can be individually adapted to the respective joining process.

The targeted use of pull tab not only improves handling and ergonomics, but also increases process reliability. In particular, contact with the adhesive surfaces is avoided, which has a positive effect on adhesive quality and reproducibility.

While pull tabs primarily facilitate handling in manual processes, they play a crucial role in automated or semi-automated applications in terms of cycle time, gripability and process stability.

However, pull tabs are neither standardised nor regulated.

The following section therefore presents different variants and manufacturing methods.

![[Translate to Englisch:] Aufgeklebte Anfasslasche [Translate to Englisch:] Aufgeklebte Anfasslasche](/fileadmin/_processed_/a/6/csm_Aufgeklebte_Anfasslasche_3941beed7c.jpg)