The most common reason for adhesive tape failure is choosing the wrong tape. However, it is rarely the tape itself that is at fault, but rather the combination of the adhesive tape and the substrate.

The most important factors to consider here are the substrate (material) to which the tape is being applied and how specific the application is.

In addition, the process steps that the adhesive tapes or moulded parts undergo in the further processing process are often not taken into account.

As far as substrates are concerned, it is important to choose the right counterpart from the wide range of rubber and acrylic adhesives available on the market. They often have different properties, which makes the choice of tape all the more important.

Therefore, make sure you can answer the following questions before selecting an adhesive tape:

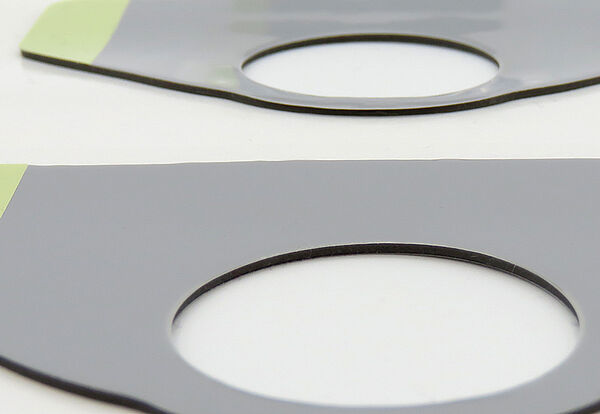

- Which substrates are to be bonded?

- What is the surface texture – smooth or rough?

- What is the surface energy of the substrates?

- Do they need to be pre-treated?

- How are the moulded parts handled in the further process?