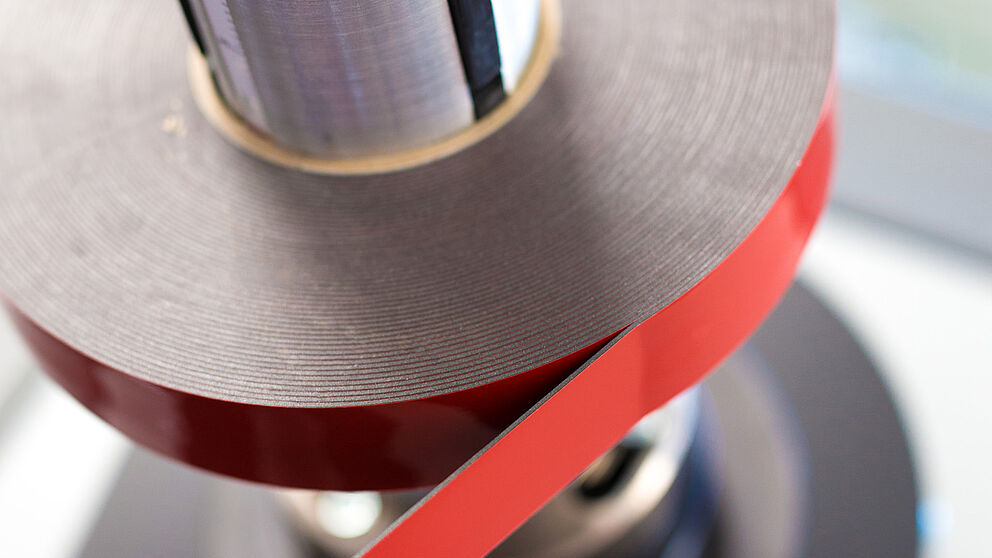

Not all tapes are PSA. Heat- or moisture-activated systems are

used for certain functional layers (e.g. elastomer sealing systems,

semi-foaming structures, NVH damping systems).

Examples:

-

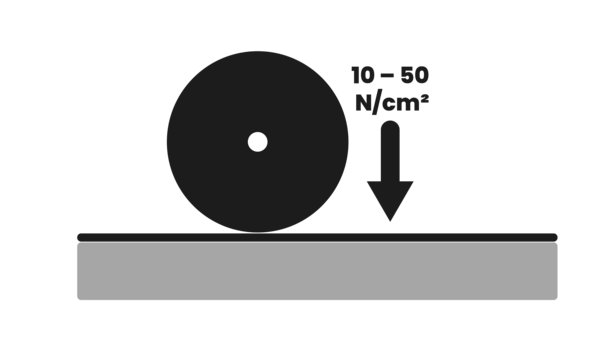

Heat-Activated Adhesives (HAA)

Adhesive only activates at >120–150 °C

-

Moisture-Cure-Tapes

React with air or component moisture

-

Latent adhesives

In laminates or bonding stacks

These systems are used specifically when PSA systems are insufficient for functional reasons (temperature, tightness, dynamic load, oil contact).