- Whitepaper

-

Case Studies

- Formular Aerofinne

- Download-Side Aerofinne

- Formular Display bonding

- Download-Side Display bonding

- Formular Glass cover bonding

- Download-Side Glass cover bonding

- Formular Illuminated Radiator Grille

- Download-Side Illuminated Radiator Grille

- Formular Light Carpet Cover Bonding

- Download-Side Light Carpet Cover Bonding

- Formular Sensor Strip Bonding

- Download-Side Sensor Strip Bonding

- Formular PBC-shielding

- Download-Side PBC-shielding

-

Blog

- Which adhesive sticks to which material?

- Customised packaging for customised moulded parts

- The difference between liquid glue and adhesive tape

- How is the tape delivered?

- Gluing is botching – The myth debunked

- What problems does adhesive tape solve

- What is a Liner?

- Preventing Tape Failure

- Optimized Material Utilization

- Adhesive tape in vehicle displays

- Adhesive tape in battery constructions

- Do you have to activate tape?

- At what point can protective foils cause damage?

- Are there adhesive tapes that conduct electricity?

- Cost Optimization in the Automotive Supply Industry

- Adhesion, cohesion and tack

- Surface energy

- How to Quickly Get the Optimal Offer

- Tags

- Videos

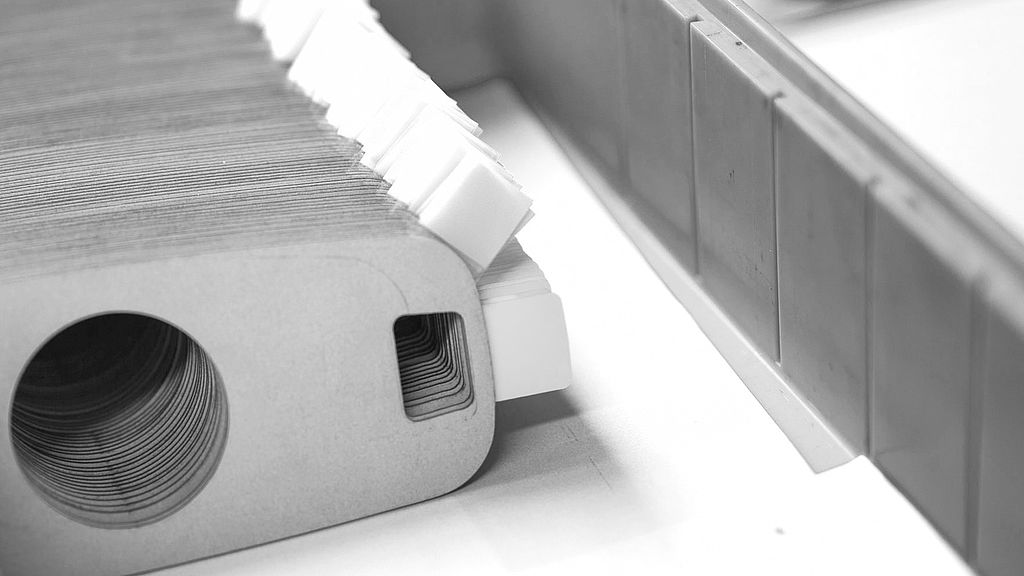

- Prototyping

- Digital Open House