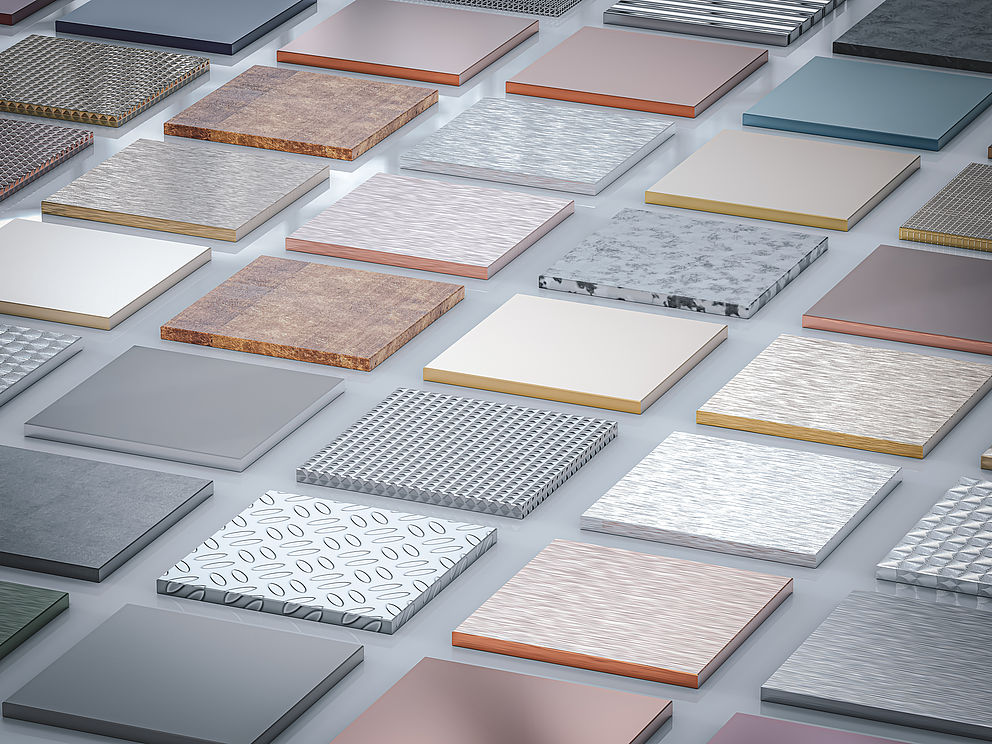

When bonding fails in industrial environments, the cause is rarely the adhesive tape itself. In practice, it is much more common for the substrate to fail — because it has not been understood, evaluated or prepared properly. The idea that "good adhesive tape = secure adhesion" is therefore too simplistic. The decisive factor is what needs to be bonded — not just what is used to bond it.

This is precisely where the flaw in the thinking behind many projects begins: The search for the "right adhesive tape" begins before the substrate has been classified. Without this assessment, any material decision is a shot in the dark — with risks of rejects, complaints and legal costs.

![[Translate to Englisch:] Icon Substrat/Materialauswahl [Translate to Englisch:] Icon Substrat/Materialauswahl](/fileadmin/user_upload/facelift/8_Blog/Auf_welchem_Material_haelt_Klebeband_/Substrat_Material.png)

![[Translate to Englisch:] Icon Oberflächenstruktur [Translate to Englisch:] Icon Oberflächenstruktur](/fileadmin/user_upload/facelift/8_Blog/Auf_welchem_Material_haelt_Klebeband_/Oberflaechenstruktur.png)

![[Translate to Englisch:] Icon Oberflächenenergie [Translate to Englisch:] Icon Oberflächenenergie](/fileadmin/user_upload/facelift/8_Blog/Auf_welchem_Material_haelt_Klebeband_/Oberflaechenenergie.png)