Material

Not all liners are the same. Depending on the application, the first thing to consider is which material is best suited. One material is more suitable for high temperatures, one prevents electrostatic charging, and yet another has the best properties in terms of tear resistance. The most common materials are PET, PP, LDPE and paper.

Siliconization

Another factor influencing the selection is the siliconization of the liner. This can be on one or both sides and can be stronger or weaker. The higher the siliconization of a liner, the easier it is for the tape to come off.

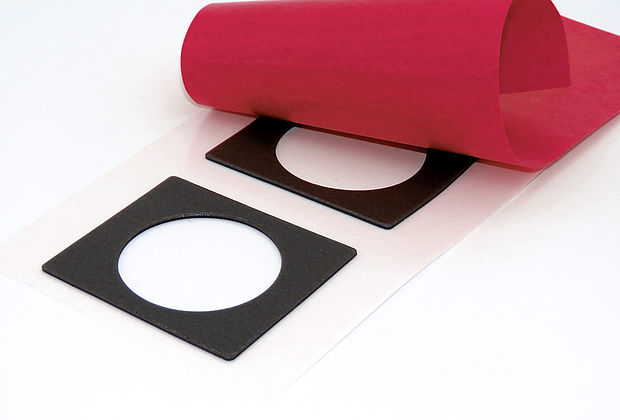

Thickness and color

Thickness and color can also be decisive. For example, only certain thicknesses are often permissible due to the process. The colors can help in the process, for example, as identification: Which liner must be detached first? Which part is installed on which side?